The grooves of the mold's injection air inlet, the surface light and shadow, the scratches on the grooves and the size of the screw holes have increased

The grooves of the mold's injection air inlet, the surface light and shadow, the scratches on the grooves and the size of the screw holes have increased

The grooving ring of the mold's injection air inlet

Phenomenon: During the production process of the bottom cover, there are air-patterned circles at the glue inlet.

Analysis: A high speed will intensify the shearing of the molten material, generating high-temperature gases that are prone to decomposition. The gas produced when the glue cylinder is melting glue; The position switch is too early.

Characteristics of injection molding machines

Grade: Haitian, Clamping force: 120t, Plasticizing capacity: 150g

(2) Mold characteristics

Mold ejection number: 1×2, glue injection method: point gate, ejection method: Ejection by ejector pin, mold temperature: 70°C (constant temperature machine)

(3) Product characteristics

Material: ABS PA757, Color: black, Product weight (single piece) : 15.7g, Spout weight: 4.75g

(4) Analysis of causes of defects

The glue feeding method is submersible glue feeding. The molten material flows to the vicinity of the glue feeding port. Due to the extremely high speed, it causes high shear, making the molten material heat up rapidly in an instant. The raw material decomposes and generates gas, which is then drawn into the mold.

2. The forming process needs improvement.

3. The environment for the melt glue cylinder needs to be improved.

(5) Countermeasures

1. Utilize multi-level injection and position switching.

2. In the first section, fill the runner opening to the glue inlet at a relatively fast speed and find the corresponding switching position. Then, in the second section, fill the area near the glue inlet at a slow speed and in a very small position. In the third section, fill 90% of the mold cavity at a medium speed, and in the fourth section, fill the mold cavity at a slow speed to completely expel the air inside the mold cavity, avoiding trapped air and charring and other adverse phenomena. Finally, switch to the pressure-holding switching position.

Auto Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

The surface light and shadow of the mold and the scratches on the texture

Phenomenon: Abnormal appearance of the mold occurs after a certain amount of production.

Analysis: The technician believes that the mold is not demolding smoothly and requests to repair the mold module to save the mold. High injection pressure will result in better light and shadow effects, but the drag damage will be more severe.

Characteristics of injection molding machines

Grade: DMG, clamping force: 100t, plasticizing capacity: 94g

(2) Mold characteristics

Mold ejection number: 1×2, glue feeding method: from large and small ports to small water ports, ejection method: Ejection by ejector pins, mold temperature: 90°C (constant temperature machine)

(3) Product characteristics

Material: ABS PA757 with silver powder, color: black with silver powder, product weight (single piece) : 5.53g, spout weight: 4.86g.

(4) Analysis of causes of defects

After the mold has been in production for a period of time, the PL surface mouth has a slight reverse mouth due to the residual glue shavings and local glue threads, which is very sensitive to pressure. If the pressure is slightly too high, there will be drag marks. However, if the pressure is relatively low, use light and shadow on the product surface.

2. Due to the structural limitations of the product, the thickness of the glue positions is inconsistent, with a large drop. There are depressions on the inner side with light and shadow, and the stress decomposition during molding is inconsistent.

(5) Countermeasures

1. Utilize multi-level injection and position switching.

2. In the first section, fill the runner opening to the glue inlet at a relatively fast speed and find the corresponding switching position. Then, in the second section, fill the area near the glue inlet at a slow speed and in a very small position. In the third section, quickly fill 90% of the mold cavity to prevent the high-temperature molten rubber from cooling down and forming a fusion line. In the fourth section, fill the mold cavity slowly to completely expel the air inside the cavity and avoid the phenomenon of trapped air. Finally, switch to the pressure-holding switching position.

Commodity Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

The size of the screw holes in the mold has increased

Phenomenon: During the production process of the rotary cover, the size of the middle hole position is 0.1mm larger.

Analysis: The technician analyzed and believed that there was an abnormality in the structural parts during the mold production process. Whether the mold has been corrected or not is unknown to everyone. The hole position is deformed.

Characteristics of injection molding machines

Grade: Haitian, Clamping force: 86t, Plasticizing capacity: 100g

(2) Mold characteristics

Mold ejection number: 1×2, glue injection method: point gate, ejection method: Ejection by ejector pin, mold temperature: 85°C (constant temperature machine)

(3) Product characteristics

Material: ABS PA767 37784, Color: black, Product weight (single piece) : 3.25g, spout weight: 2.83g

(4) Analysis of causes of defects

The glue position in the middle hole of the rotary cover body is relatively thick. Before demolding, it needs to be cooled for a relatively long time to ensure no shrinkage and strength.

2. The temperature of the rear mold is too high.

(5) Countermeasures

1. By using multi-stage injection and position switching, the front and rear molds are separately connected for cooling and water supply.

2. In the first section, fill the runner opening at a relatively fast speed and find the corresponding switching position. Then, in the second section, fill the area near the glue inlet at a slow speed and a very small position. The third section is to quickly fill the mold cavity to completely expel the air inside the cavity, avoiding trapped air and charring and other adverse phenomena. Finally, switch to the pressure-holding switching position.

Related News

Multiple mold designs

2025-07-25

Multiple mold designsIn-mold labeling processThin-walled plastic packaging produ...

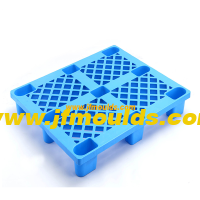

Key equipment in the field of logistics and warehousing

2025-06-29

Key equipment in the field of logistics and warehousingTray mold Manufacturer in...

Focus on quality and deeply cultivate innovation

2025-07-05

Focus on quality and deeply cultivate innovation In daily life, from the mobi...

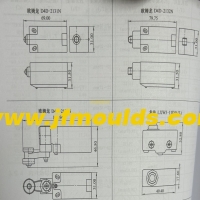

Types and basic requirements of mold design drawings

2025-09-07

Types and basic requirements of mold design drawingsTo shorten the production cy...

The positioning ring and screws of the mold

2025-10-07

The positioning ring and screws of the moldOne: Positioning circleThere are two ...

The limit switch of the mold

2025-10-08

The limit switch of the mold In some cases, the actions of different mechan...