Key equipment in the field of logistics and warehousing

Key equipment in the field of logistics and warehousing

Tray mold Manufacturer in China (jfmoulds.com)

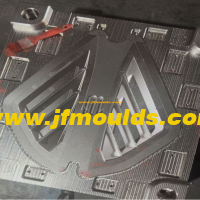

Characteristics and Classification of 1. Pallet Mould

As a standardized basic instrument of modern logistics and warehousing industry, pallets bear the key functions of cargo carrying, handling and storage. As the core tool for the production of pallets, the pallet mold is the key to ensure the quality, performance and production efficiency of the pallet. Driven by injection molding technology, injection pallet molds have become the mainstream choice for pallet production because of their high efficiency, flexibility and low cost. This paper will deeply analyze the characteristics, technical points and industry application of injection pallet mold. Pallet mold has the following characteristics:

1. Large-scale and high-strength design

Pallet sizes are generally large (common specifications are1200mmx1000mm,1100mmx1100mm), the mold needs to adapt to large-size cavities, and needs to withstand up100~200Tons of injection pressure. In order to ensure that the mold does not deform under high pressure, thickened mold frame, high-strength mold steel (suchP20,718h), and enhance the rigidity of the mold by optimizing the layout of reinforcing ribs.

2.Structural Complexity and Functional Integration

Pallets need to take into account the carrying capacity, anti-skid performance, forklift/AGVAdaptability and other functions, mold design needs to integrate a variety of structures:

Reinforcement system: through the three-dimensional grid or Sichuan-shaped reinforcement design, improve the rigidity of the pallet, the mold needs to accurately control the thickness and spacing of the ribs;

Anti-slip texture: in the mold surface processing point, striped texture, to ensure the safety of cargo handling;

Fork hole structure: precise design of fork hole size and tilt angle, suitable for different types of handling equipment.

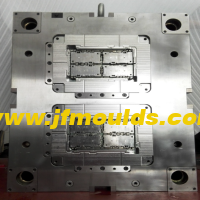

3.Multi-cavity design and productivity

In order to meet the massive demand for pallets in the logistics industry, molds often use multi-cavity designs (such2Cavity,4cavity), and with hot runner technology to achieve synchronous injection molding, the single-piece production cycle is compressed.30~60seconds, significantly increase production capacity

According to the material and structure of the pallet, the pallet mold can be divided into plastic pallet mold, metal pallet mold and composite pallet mold. Among them, the plastic tray mold is the most widely used, because the plastic tray has the advantages of light weight, corrosion resistance, low cost and so on. Plastic pallet mold can be divided into flat pallet mold, grid pallet mold, Sichuan word pallet mold, Tian word pallet mold and so on according to the shape and function of the pallet.

Second, the design points of the pallet mold

1.Product Analysis and Process Planning:

Before designing a pallet mold, it is necessary to analyze the pallet product in detail, including the size, shape, carrying capacity, and use environment of the pallet. According to product requirements, formulate a reasonable injection molding process plan, determine the model of the injection molding machine, injection pressure, injection speed, holding time, cooling time and other process parameters.

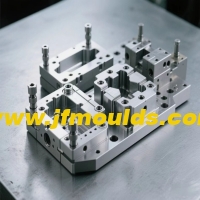

2.mold structure design:

Parting surface design: The choice of parting surface directly affects the structure of the mold and the demolding method of the pallet. The appropriate parting surface should be selected according to the shape and size of the tray to ensure that the tray can be demoulded smoothly, while minimizing the difficulty and cost of mold processing.

Gating system design: Due to the large size of the tray, it is necessary to design the gating system reasonably to ensure that the plastic melt can fill the cavity evenly. Multi-point pouring is usually used to shorten the flow distance of the plastic and reduce the generation of weld lines. At the same time, pay attention to the location and size of the gate to avoid gate marks affecting the appearance and performance of the tray.

Cooling system design: The cooling system design of the pallet mold is very important, which directly affects the production efficiency and quality of the pallet. Due to the large size of the tray and the wide cooling area, it is necessary to design a reasonable cooling water circuit to ensure that the mold can be cooled quickly and evenly. The cooling efficiency can be improved by circulating water cooling, optimizing the layout of cooling pipes, and increasing the flow rate of cooling medium.

The design of the ejection system: the tray needs a large ejection force when demolding, so the design of the ejection system should be reasonable and reliable. Usually, a combination of ejector pins, ejector blocks, push plates and other ejection methods is used to ensure that the tray can be ejected smoothly from the mold to avoid ejection deformation or damage.

Reinforcing ribs and structural design: In order to improve the carrying capacity and rigidity of the pallet, it is necessary to set reinforcing ribs at the appropriate position of the pallet. In the mold design, it is necessary to accurately reflect the shape and position of the reinforcing ribs to ensure the forming quality of the reinforcing ribs. At the same time, the structural strength of the mold should be considered to prevent the mold from being deformed or damaged during the injection molding process.

3, material selection and die life:

Pallet molds usually need to withstand greater injection pressure and frequent mold opening and closing actions, so the strength, wear resistance and toughness of the mold material are required to be high. General selection of high quality die steel, suchP20,718And carry out appropriate heat treatment to improve the service life of the mold. In addition, in the mold design, it is necessary to reasonably design the structure of the mold and the size of the parts to avoid stress concentration and extend the service life of the mold.

Manufacturing and Quality Control of Pallet Mould

1.Manufacturing process: The manufacturing process of the pallet mold is similar to that of the ordinary injection mold, but due to its large-scale and complex structure, some special problems need to be paid attention to during the processing. For example, the processing of large molds requires the use of large processing equipment, such as large CNC machining centers, gantry milling machines, etc., to ensure machining accuracy and efficiency. For complex structural components, it may be necessary to use special processing techniques such as EDM and wire cutting. In the process of mold assembly, it is necessary to strictly control the matching accuracy of the parts to ensure the overall performance of the mold.

2.Quality control: The quality of the pallet mold directly affects the quality and production efficiency of the pallet. In the mold manufacturing process, it is necessary to establish a strict quality control system, from raw material inspection, processing process monitoring to finished product inspection, every link must be strictly controlled. Adopt advanced detection equipment and detection methods, such as three-coordinate measuring instrument, optical projector, etc., to detect the key size and shape of the mold to ensure that the accuracy of the mold meets the design requirements. At the same time, it is necessary to test and debug the mold, test the molding performance and product quality of the mold through the mold, find and solve problems in time, and ensure that the mold can be put into production normally.

Application and Development Trend of Pallet Mould in Logistics Storage Industry

Pallets produced by pallet molds are widely used in the logistics and warehousing industry and are an important tool for realizing the unitization of goods and standardized transportation and storage. With the rapid development of the logistics industry, the demand for pallets is increasing, and the quality and performance of pallets are also put forward higher requirements. This has prompted the continuous innovation and development of the pallet mold industry, showing the following development trends:

1.Research and development of high-performance pallet molds: In order to meet the requirements of the logistics industry for pallet carrying capacity, service life and environmental performance, the development of high-performance pallet molds has become a trend. For example, the development of high-strength, lightweight plastic pallet molds, the use of new materials and structural design, improve the performance and quality of the pallet.

2.Intelligent and automated production: the introduction of intelligent and automated technology to improve the production efficiency and quality stability of pallet molds. For example, the use of automated processing equipment and production lines to realize the automated processing and assembly of molds; the use of mold monitoring systems to monitor the working status and production process of molds in real time, and to find and solve problems in time.

3.Customized services: according to the needs of different customers, to provide customized pallet mold solutions. With the diversified development of the logistics industry, customers have more and more personalized requirements for the shape, size and function of pallets. Pallet mold enterprises need to have the ability to quickly respond to customer needs, customize the design and manufacture of molds.

4.Green manufacturing and sustainable development: Pay attention to green manufacturing and sustainable development, adopt environmentally friendly materials and energy-saving technologies to reduce energy consumption and environmental pollution in the mold production process. For example, promote the use of biodegradable plastic materials to make pallets, develop energy-saving injection molding processes and mold structures, and achieve sustainable development of the pallet mold industry.

Four, injection pallet mold industry applications and cases

1. Logistics and warehousing field

In the e-commerce, express delivery, manufacturing automated storage scenarios, Sichuan pallet mold is widely used. For example, a logistics company customized a four-way fork-shaped pallet mold, by optimizing the fork hole bevel design, so that the pallet and.The adaptation efficiency of AGV robots is increased by 20%, with an annual production capacity of 500000 pieces.

2. Food and pharmaceutical industry

Food grade tray mold needs to meetFDA,ISO 14644 and other standards, often using mirror polishing process (Ra≤ 0.2 μm) and corrosion-resistant materials (such as S136). A special tray mold for a clean room of a pharmaceutical enterprise, through in-mold labeling (IML) technology, is integrally formed on the surface of the tray with a traceable two-dimensional code to realize the whole process quality control.

3. Automobile manufacturing industry

In the automobile manufacturing process, the transportation and storage of parts require a large number of pallets. Battery box tray mold production tray, usually usingSMC (sheet molding compound) or carbon fiber reinforced composite materials are manufactured with the advantages of light weight, strong rigidity, and corrosion resistance. It not only meets the needs of lightweight auto parts, but also effectively protects parts during transportation and storage. damage. At the same time, the design of the mold also takes into account the strength, heat dissipation, fire prevention and integration and other aspects of performance, such as the structure of the integrated cooling system, to achieve rapid heat dissipation, to meet the automotive manufacturing industry's stringent requirements for the transportation and storage of parts.

4. Special function tray customization

Anti-static tray: mold surface processing grid-shaped conductive slot, with anti-static material injection molding, to meet the storage needs of electronic components;

Refrigerated tray: designed by double-layer hollow structure mold, filled with insulation material after injection molding, used for cold chain transportation.

Tray mold Manufacturer in China (jfmoulds.com)

Related News

From principle to application, understand this "shaping master" in industry

2025-07-16

From principle to application, understand this "shaping master" in industry P...

The screw columns of the mold are prone to damage and weld marks/shrinkage

2025-08-07

The screw columns of the mold are prone to damage and weld marks/shrinkageThe sc...

The demolding types of two-plate molds

2025-07-22

The demolding types of two-plate molds1.1 Injection-molded parts without overhan...

Special mold design

2025-07-24

Special mold design1 Stacked moldThe stacked mold simultaneously produces inject...

The drawing of the mold and the inking of the gate

2025-08-05

The drawing of the mold and the inking of the gateMold drawing Phenomenon: Th...

Multiple mold designs

2025-07-25

Multiple mold designsIn-mold labeling processThin-walled plastic packaging produ...