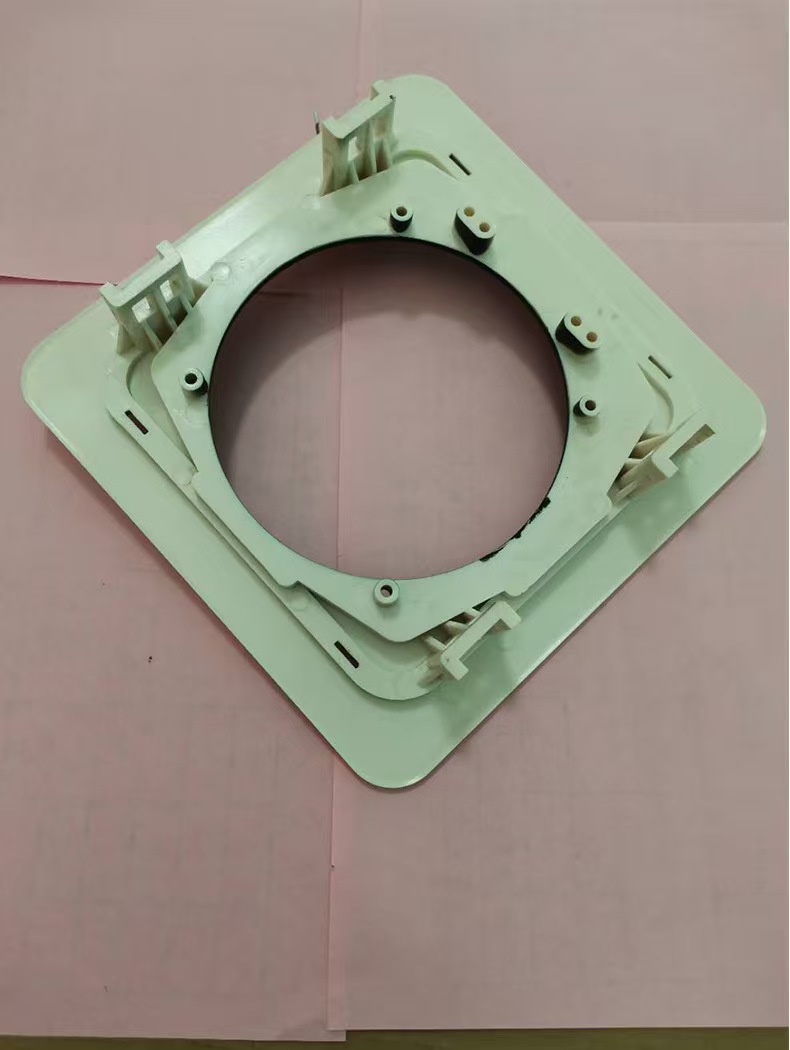

The glue inlet position of the mold is dragged and charred

The glue inlet position of the mold is dragged and charred

The glue inlet of the mold is scratched

Phenomenon: Drag marks were found at the glue inlet position after the product was demolded.

Analysis: 1. The technician believed that the mold was not demolding smoothly and requested that the mold be repaired and rented to save the mold.

2. If the injection pressure is too low, the product will shrink.

(1)Characteristics of injection molding machines

Grade: Haitian, Clamping force: 120t, Plasticizing capacity: 150g.

(2) Mold characteristics

Mold ejection number: 1×2, glue injection method: submersible, ejection method: Ejection by top block, mold temperature: Front mold 110°C, rear mold 95°C (constant temperature machine)

(3) Product characteristics

Material: PC K3037087, Color: Transparent grey, Product weight (single piece) : 10.16g, nozzle weight: 5.8g

(4) Analysis of causes of defects

1. The product was not cooled enough before being demolded.

2. The rubber inlet for diving is too large.

3. The mold opening speeds for boards A and B were not set properly.

(5) Countermeasures

1. Reduce the size of the glue inlet again and apply multi-stage injection and position switching.

2. In the first section, fill the flow channel to the glue inlet at a relatively fast speed and find the corresponding switching position. Then, in the second section, fill the area near the glue inlet at a slow speed and a very small position. The third section should be filled rapidly to 90% of the mold cavity to prevent the high-temperature molten rubber from cooling and forming wavy patterns. In the fourth section, fill the mold cavity slowly to completely expel the air inside the cavity, avoiding trapped air and charring and other adverse phenomena. Finally, switch to the pressure-holding switching position.

Injection molding process table

Injection molding machine: Haitian 120T, Type A screw, injection capacity 150g | Product Name: Protective Cover | ||||

Raw material: PC K30 | Color: Transparent grey | Drying temperature: 110°C | Drying method: Dehumidifying dryer | Drying time: 4 hours | Recycled material usage: 0 |

Finished product weight: 10.16g×2=20.32g | Nozzle weight: 5.8g | Mold output: 1×2 | The method of pouring glue into the gate: pouring glue into the water | ||

Barrel temperature | Mold temperature | Use machines | "Settings | "Actual | ||||

| 1 | 2 | 3 | 4 | 5 | before | Constant temperature machine | 110°C | 105°C |

| 310°C | 300°C | 290°C | 240°C | 80°C | ||||

| △ | △ | △ | △ | △ | after | Constant temperature machine | 95°C | 92°C |

| △ | △ | △ | △ | △ | ||||

| / | 90 | 95 | Holding pressure | 100 | 105 | 115 | 115 | Injection pressure | |

| / | 1.0 | 1.1 | Holding pressure time | 20 | 30 | 30 | 40 | Injection velocity | |

Residual amount of injection glue | / | 10 | 10 | Pressure-holding position | 13 | 13 | 34 | Velocity of fire position | |

| 7.8 | / | / | / | / | 2.0 | Velocity of fire time |

Intermediate time | Injection time | Cooling time | The entire duration | Back pressure | Rotational speed | Retraction speed | Material quantity position | Retraction position |

| 1 | 3.5 | 24 | 45 | 5 | 10 15 10 | 10 | 40 | 3 |

Mold closing time | Supervise the feeding time | Clamping force | Ejection length | Ejection times | Rotation position | Blowing delay | Blowing time |

| 1 | 10 | 120 | 45 | 1 | 15 35 38 | / | / |

Motorcycle Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

The mold is charred.

Phenomenon: During the production process of injection molded products, there is often a phenomenon of charring and blackening near the very end.

Analysis: High speed will cause material melting, intensify shearing, generate high temperatures and be prone to decomposition. The surface of the mold is smooth. If the shooting speed is fast, it is prone to high temperature and decomposition. The position switch was too late.

(1)Characteristics of injection molding machines

Grade: Haitian, Clamping force: 86t, Plasticizing capacity: 119g.

(2) Mold characteristics

Mold ejection number: 1×2, glue injection method: point gate, ejection method: Ejection by ejector pin, mold temperature: 110°C (constant temperature machine)

(3) Product characteristics

Material: ABS, Color: Gray, Product weight (single piece) : 3.09g, sprue weight: 3.15g

(4) Analysis of causes of defects

The main channel of the mold is very large, and the glue inlet method is submersible glue inlet. When the molten material flows near the glue inlet, due to the excessive speed and the very smooth surface of the mold, high shear occurs, causing the molten material to heat up rapidly in an instant. The gas produced by the decomposition of raw materials cannot be discharged in time, resulting in charring.

(5) Countermeasures

1. Utilize multi-level injection and position switching.

2. In the first stage, use a moderate injection speed to just fill the runner opening to the glue inlet and find the corresponding switching position. Then, in the second stage, use a slow speed and a very small position to fill the area near the glue inlet. In the third section, fill the mold cavity at a medium speed to 97% to prevent the high-temperature molten rubber from cooling. In the fourth section, fill the mold cavity at a slow speed to completely expel the air inside the cavity, avoiding trapped air and charring and other adverse phenomena. Finally, switch to the pressure-holding switching position.

Injection molding process table

Injection molding machine: HTAN 86T, Type B screw, injection volume 119g | Product Name: Switch Lever | ||||

Raw material: ABS PA757 | Colour: Grey | Drying temperature: 85°C | Drying method: Dehumidifying dryer | Drying time: 3 hours | Recycled material usage: 10% |

Finished product weight: 3.09g×2=6.18g | Nozzle weight: 3.15g | Mold output: 1×2 | Gate injection method: Point gate | ||

Barrel temperature | Mold temperature | Use machines | "Settings | "Actual | ||||

| 1 | 2 | 3 | 4 | 5 | before | Water temperature machine | 110°C | 98°C |

| 245°C | 240°C | 230°C | 220°C | / | ||||

| △ | △ | △ | △ | △ | after | Water temperature machine | 110°C | 96°C |

| △ | △ | △ | △ | △ | ||||

| / | 89 | Holding pressure | Pressure-holding position | 80 | 110 | 120 | Injection pressure | ||

| / | 1.5 | Holding pressure time | 13 | 12 | 13.7 | 18 | Injection pressure position | ||

Residual amount of injection glue | / | 10 | / | 55 | 3 | 7 | 9 | Injection velocity | |

| 10.3 | / | / | / | 12 | 12 | 13.7 | 18 | Velocity of fire position |

Intermediate time | Injection time | Cooling time | The entire duration | Back pressure | Rotational speed | Retraction speed | Material quantity position | Retraction position |

| 1 | 1.6 | 9 | 19.6 | 3 | 40 55 43 | 10 | 22 | 1.5 |

Mold closing protection time | Supervise the feeding time | Clamping force | Ejection length | Ejection times | Rotation position | Blowing delay | Blowing time |

| 1 | 10 | 600KN | 45 | 1 | 15 22 23.5 | / | / |

Commodity Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

Related News

The mold case integrates lines and exposed white

2025-08-04

The mold case integrates lines and exposed whiteMold fusion line:Phenomenon: The...

The causes and solutions of poor welding in injection molding, product cracks and product deformation

2025-07-30

The causes and solutions of poor welding in injection molding, product cracks an...

The limit switch of the mold

2025-10-08

The limit switch of the mold In some cases, the actions of different mechan...

Injection molds: The "Industrial Gene" Hidden Behind Everything

2025-07-12

Injection molds: The "Industrial Gene" Hidden Behind Everything When our fing...

The cavity arrangement and parting surface of the mold

2025-10-09

The cavity arrangement and parting surface of the mold Forming parts refer ...

A collection of mold manufacturing processes, standards, processes and cases.

2025-06-19

The process flow chart is as follows: all kinds of tools and products used in ou...