Wire clamping and air marks near the screw holes of the mold

Wire clamping and air marks near the screw holes of the mold

Phenomenon: Wire jamming near the screw holes of the D16 transparent shell.

Reason: The presence of holes causes the two strands of raw materials to converge during molding, resulting in wire clamping, which is difficult to improve.

Analysis: During the forming process, when the raw material meets the mold column, two strands of raw material are formed. When they are finally welded, wire clamping occurs on the product. Product

It is a transparent part with obvious wire clamping. The mold has poor exhaust.

Characteristics of injection molding machines

Grade: DEMAG50T, clamping force: 5ot, plasticizing capacity: 80g

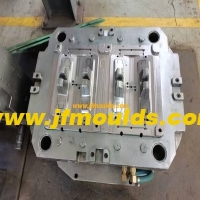

(2) Mold characteristics

Mold ejection number: 1×1, glue injection method: large water injection, ejection method: Ejection with ejector pins, mold temperature: 125° C

(3) Product characteristics

Material: PCTY-1101, Color: Transparent, Product Weight: 23.86g, Nozzle weight: 4.68g

(4) Analysis of causes of defects

During the forming process, the raw materials encounter the mold columns to form two strands of raw materials. When they are finally welded, wire clamping occurs on the product. Due to the product

It is a transparent part and has no oil spraying process, so the wire clamping is obvious.

(5) Countermeasures

1. Utilize multi-level injection and position switching.

2. In the first section, use a slow speed to just fill the flow channel to the glue inlet and find the corresponding switching position, and then use a medium constant speed in the second section

And the smaller positions are filled through the part near the glue inlet for molding. Fill 90% of the mold cavity at a moderate speed in the third section to avoid the high temperature of melting

The rubber compound cools down. In the fourth stage, fill the mold slowly to completely expel the air in the mold cavity, avoiding trapped air and charring and other adverse phenomena.

3. Increase the temperature of the mold.

4. Add an exhaust vent at the wire clamping point.

Auto Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

"Air pattern"

Phenomenon: Air streaks near the glue entry point of the D16 rotating shaft decorative part.

The reason is that the glue inlet is too small, and air streaks are prone to occur near the glue inlet point during the molding process.

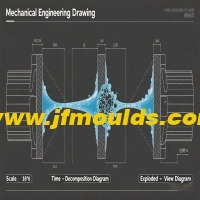

Analysis: High speed will cause material melting, intensify shearing, generate high temperatures that are prone to decomposition, and make gas discharge difficult. The shooting speed of the smooth surface product is too fast

It is prone to high temperatures and decomposition. The mold has poor exhaust.

Characteristics of injection molding machines

Grade: HT86T, Clamping force: 86t, plasticizing capacity: 119g

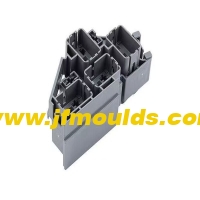

(2) Mold characteristics

Mold ejection number: 1x2, injection method: step gate, ejection method: Ejection pin and inclined ejection, mold temperature: 119 ° C

(3) Product characteristics

Material: PCEXL 1414, Color: Gray, Product weight: 2.64g, nozzle weight: 3.82g

(4) Analysis of causes of defects

The injection port method is stepped injection. Due to the small injection cross-section, the speed is too fast when the pressure is constant, and the mold surface is very smooth.

The high shear caused the molten material to heat up rapidly in an instant, leading to the decomposition of raw materials and the generation of gas. The gas was not discharged in time and was produced at the water outlet Anger lines.

(5) Countermeasures

1. Utilize multi-level injection and position switching.

2. In the first section, fill the flow head just to the glue inlet at a moderate speed and find the corresponding switching position. Then the second section is formed by filling the area near the glue inlet at a slow speed and in a very small position. The third section should be filled rapidly to 90% of the mold cavity to prevent the high-temperature molten rubber from cooling. The fourth section should be filled slowly to ensure that all the air inside the mold cavity is completely expelled, avoiding trapped air and charring and other adverse phenomena.

3. Add venting near the gate and finally switch to the pressure-holding switching position.

4. Increase the mold temperature.

5. Increase the cross-sectional area of the glue inlet.

Commodity Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

Related News

Tolerance and fit of injection molds

2025-09-11

Tolerance and fit of injection moldsI. Common tolerances and fits of parts in in...

The mold case integrates lines and exposed white

2025-08-04

The mold case integrates lines and exposed whiteMold fusion line:Phenomenon: The...

Injection molds: The Cornerstone of Precision Manufacturing and New Trends in Industry Development

2025-07-08

Injection molds: The Cornerstone of Precision Manufacturing and New Trends in In...

The U-shaped position of the mold is filled with water lines and trapped air, which turns white

2025-08-06

The U-shaped position of the mold is filled with water lines and trapped air, wh...

The causes and solutions of bubbles, mold sticking and gate sticking in injection molded products

2025-07-31

The causes and solutions of bubbles, mold sticking and gate sticking in injectio...

The methods for adjusting parameters for defects in injection molded products are as follows

2025-08-01

The methods for adjusting parameters for defects in injection molded products ar...