The causes and solutions of bubbles, mold sticking and gate sticking in injection molded products

The causes and solutions of bubbles, mold sticking and gate sticking in injection molded products

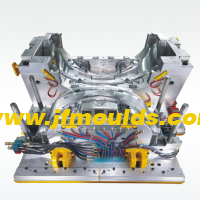

Auto Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

Product defect | Possible reasons | Solution |

Bubbles in the product | 1.The plastic is damp, containing moisture, solvents or volatile substances. 2. The material particles are too fine, uneven or have low back pressure, the temperature at the rear end of the barrel is high, or air is mixed in at the feeding end or the material is backflowed and turned over. 3. Insufficient filling in the mold cavity or too small gates and runner channels. 4. The injection pressure and speed Settings are too low. 5. The injection time setting is too low. 6. The mold temperature is low or uneven, and the nozzle temperature is too high. | 1.Before injection molding, the rubber compound should be dried first, and it is also necessary to avoid large temperature changes during the processing. 2. For fine particles or uneven materials, set the temperature at the end of each zone of the barrel properly to prevent air from entering during injection molding. 3. Expand the gate and runner dimensions, and check the discharge port or injection action parameters. 4. Increase the set values of injection pressure and speed. 5. Increase the setting value of the injection time parameter. 6. Inspect the mold cooling system, rearrange it to ensure the temperature of the working mold is consistent, and reduce the set temperature value of the nozzle. |

| Product sticking to the mold | 1.The gate size is too large or the draft Angle of the cavity is too small. 2. The demolding structure is unreasonable or there is an inverted position inside the die. 3. The inner wall of the tool and die is not smooth enough or has dents and scratches. 4. The temperature is too high or the injection pressure is too large. 5. The injection time parameter is set too long. 6. The cooling time parameter is set too short. 7. The surface of the product in the mold has not cooled and hardened or the mold temperature is too high. 8. The nozzle temperature is low, and the arc of the nozzle does not match that of the gate sleeve or. 9. There are impurities at the nozzle hole diameter or the gate sleeve hole diameter is smaller than the nozzle hole diameter due to poor fit. | 1.Modify the design dimensions of the mold gate and cavity. 2. The mold structure should be reasonable. Remove the inverted part, grind and polish it, and increase the slope of the demolding part. 3. Polish the inner wall of the model cavity again. After grinding and treating the dents and scratches, polish it again. 4. Reduce the material temperature, decrease the injection pressure, and lower the screw speed or back pressure. 5. Reduce the set value of the injection time parameter. 6. Increase the setting value of the cooling time parameter. 7. Extend the holding pressure time and enhance the cooling of the working die to reduce the die temperature. 8. Reduce the temperature of the nozzle, adjust or repair it to make the nozzle fit the gate sleeve. 9. Remove impurities from the nozzle hole and the gate sleeve, and replace the nozzle hole diameter or modify the gate sleeve hole diameter. |

| The gate is stuck to the mold | 1.The gate dimension is insufficient or no release agent is used. 2. The gate is too large or the cooling time is too short. 3. High material temperature, short cooling time, and poor shrinkage. 4. There are damages or dents on the surface of the tool and die. 5. Excessive injection pressure causes the product not to fully protrude when demolded, or the remaining part breaks the broken glue inside the mold. 6. Excessive injection pressure causes the holes in complex cavities to be blocked, forming glue columns and leading to needle breakage. | 1.Increase the degree of drowsiness by using an appropriate amount of detilli. 2. Extend the cooling time and reduce the gate diameter. 3. Reduce the material temperature and increase the cooling time to ensure good shrinkage. 4. Repair the model cavity and polish the surface. 5. Adjust the process technical parameters, such as reducing the pressure of the paper injection stock and the action parameters of the ejector pin, to prevent adhesive breakage. 6. Adjust the process parameters. Reduce the injection pressure or progress to prevent needle breakage. |

| Flash on the product | 1.The temperature of the plastic and the die is too high. 2. The injection pressure is too high or the plastic has excessive fluidity. 3. Asymmetry on both sides of the die or uneven clamping force. 4. Imbalance of the template or deformation of the guide pins leads to poor parallelism of the mold. 5. The injection time is set too long. 6. There are obstructions on the die edge, causing poor sealing of the parting surface, or partial sliding of the cavity and core, and the original size between parts is too large. | 1.Reduce the temperature of the plastic heating cylinder and the working die. 2. Reduce the injection pressure or speed. 3. Adjust the symmetry of the working die and the mold, and adjust the clamping force parameters. 4. Adjust and balance the mold and template to ensure even force distribution on all four sides. 5. Reduce the setting of the shooting and receiving time parameter. 6. Clean and polish the edges. Repair or replace parts that are too large. |

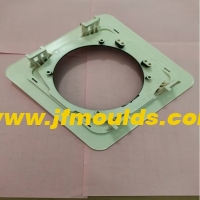

Commodity Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

Related News

Basic processing items and requirements for mold base

2025-09-30

Basic processing items and requirements for mold base(1) Fixed mold A plate and ...

The U-shaped position of the mold is filled with water lines and trapped air, which turns white

2025-08-06

The U-shaped position of the mold is filled with water lines and trapped air, wh...

Check the thickness of the wall

2025-09-17

Check the thickness of the wallThe principles for designing the wall thickness o...

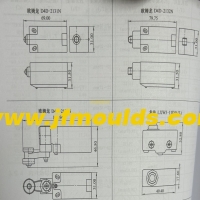

The limit switch of the mold

2025-10-08

The limit switch of the mold In some cases, the actions of different mechan...

Classification of injection molds

2025-09-06

Classification of injection moldsDifferent types of molds have different require...

The glue inlet position of the mold is dragged and charred

2025-08-06

The glue inlet position of the mold is dragged and charredThe glue inlet of the ...