The setting of injection molding pressure and flow parameters

The setting of injection molding pressure and flow parameters

1.Setting of injection molding pressure parameters

During the injection action, in order to overcome the flow resistance of the flame-molten adhesive roughly passing through the nozzle, gate opening and mold control, etc., the injection

The rubber screw must apply sufficient pressure to the molten rubber compound to complete the injection. Injection molding machines mainly consist of injection and clamping parts. Pressure parameters such as injection pressure and clamping pressure (clamping force) are important process technical parameters for injection molding. Injection molding pressure parameters include injection pressure, clamping pressure, holding pressure, back pressure, and other action pressures, etc. The specific pressure parameters are as follows.

Commodity Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

(1) Injection pressure

Injection pressure, also known as injection pressure, is the most important pressure parameter in injection molding. It plays a decisive role in the flow performance of the molten rubber compound and the filling of the mold cavity, and also has a direct impact on the dimensional accuracy and quality of injection molded products. Injection pressure

The force parameter Settings vary according to different models. Among common models, there are generally one-stage, two-stage and three-stage injection pressures. Models like Yilida have a three-level injection pressure setting. The commonly used Chunghwa injection molding machines and LK injection molding machines have a four-stage injection pressure setting. The Haitian injection molding machine has six injection pressure parameters. In specific production, pressure parameters should be reasonably selected and set based on plastic raw materials, the structure of specific molded products, etc.

(2) Setting of clamping pressure parameters

The clamping pressure is set from the low-pressure clamping, through the high-pressure clamping, until the clamping is terminated. The mold locking action is divided into

There are three stages. At the beginning of the mold locking, set the pressure parameters required for the rapid movement of the template to save cycle time and improve efficiency. When the clamping action is about to end, in order to protect the mold, eliminate the inertial impact and reduce the clamping pressure parameter. When the mold is completely closed, in order to achieve the preset clamping force, increase the set value of the clamping pressure parameter. Some models adopt a four-stage parameter setting of fast → slow → low pressure → high pressure to complete the setting of the clamping pressure, such as the LK injection molding machine, etc. The model of the Zhenxiong injection molding machine adopts four parameter Settings: low-pressure clamping, high-pressure clamping, clamping force, and clamping termination.

(3) Setting of holding pressure

Holding pressure is the process of continuing to compact the molten rubber compound in the mold cavity after the injection action is completed, filling the gaps that occur due to the cooling and shrinking of the product in the mold cavity, and increasing the density of the product. The holding pressure ensures that the pressure in the mold cavity remains constant until the gate solidifies. The holding time is often set to control the holding pressure. There are parameter Settings for the first and second pressure-holding stages, which are adopted by machines such as Chung Hsing machines, Yilida machines, Baoyuan machines, and Hengsheng machines. Some models also have multi-stage pressure-holding parameter Settings. For instance, LK machines offer pressure-holding Settings ranging from stage one to stage four, while Haitian machines have pressure-holding parameter Settings ranging from stage one to stage five. The holding pressure determines the parameter size of the feeding displacement and the consistency, uniformity, and compactness of the product quality, which is of great significance for improving product quality and production efficiency. The general principle for setting the holding pressure parameter is that the holding pressure should be slightly less than the filling force, and the gate holding time should be longer than the curing time.

(4) Setting of back pressure parameters

Back pressure is generated during the plasticizing and metering process of plastic raw materials in the melt cylinder, at the top of the screw and the front end of the melt cylinder

The pressure that the molten rubber compound experiences when the screw rotates and retreats is often referred to as plasticizing pressure. The back pressure nozzle stops the screw from retreating too quickly to ensure a uniform and fine plasticizing process. Appropriately setting the pressure parameters can increase the internal stress of the molten material, improve homogeneity and mixing effect, and enhance the physical and chemical properties of injection molding.

(5) Parameter Settings for other action pressures

The pressure Settings for each action of the injection molding machine are all carried out by using proportional pressure solenoid valves to set the action pressure parameters. They can also be conveniently adjusted and preset to ensure that the injection molding machine operates in the best working condition and completes production operations with quality and quantity guaranteed.

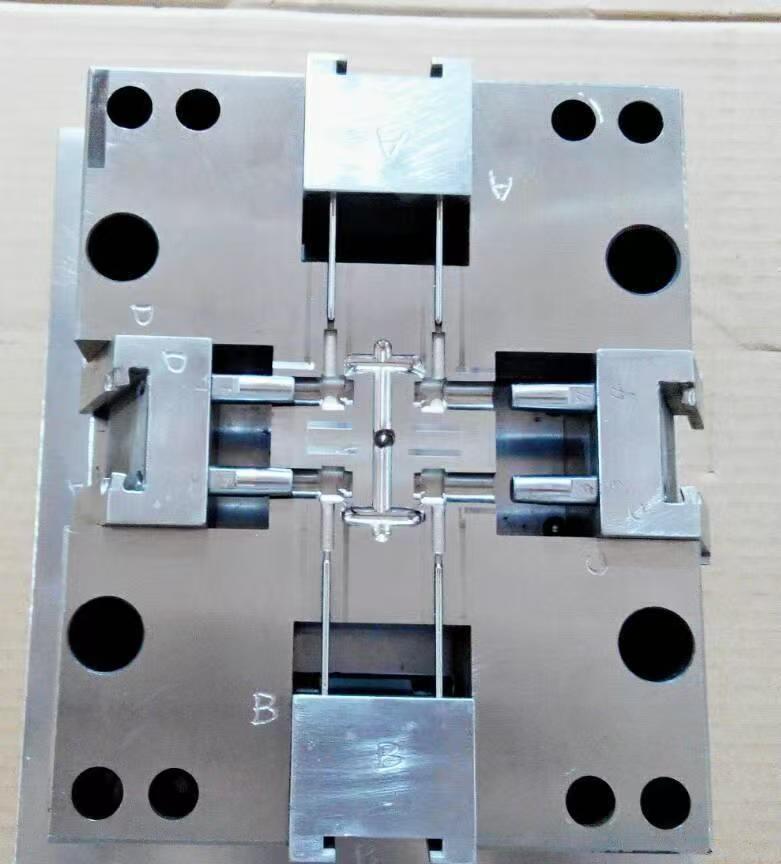

Auto Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

2. Setting of Injection molding flow parameters

Flow parameters include injection speed, melt speed, mold opening action speed, mold locking action speed, etc.

(1) Injection speed

The injection speed has a direct impact on the flow performance of the molten rubber compound, the molecular arrangement direction and surface condition in plastic products.

The injection speed drives the flow of the molten rubber compound, generating uniform shear force between adjacent flow layers, which stably propels the molten rubber compound to fill the mold

It has a significant impact on the quality and precision of injection-molded products. The injection speed parameter Settings for different models are different. Among the common injection molding machine models, the Hsin Hsiung injection molding machine has one to five injection speeds, while the LK injection molding machine has one to four injection speeds. The injection speed and injection pressure should complement each other and be used in combination. The setting of the injection speed usually starts from the first stage of injection and goes through the second stage of injection... Until the glue injection stops. The setting of the injection speed is also determined by taking into account the characteristics of the plastic raw materials and the comprehensive parameters such as the shape, size and precision of the injection molding mold design. The speed of injection will affect the quality and grade of the formed products.

(2) Mold locking and mold opening speed

The parameter Settings for mold locking and mold opening speeds are basically the same as those for pressure parameters. For example, the three stages of mold opening action speed, the first In the first stage, to reduce mechanical vibration, at the beginning of the mold opening action, the movement of the moving template is required to be slow. This is because the injection molded product is in the cavity. If the mold is opened too quickly, there is a possibility of damaging the plastic part. Opening the mold too fast can also produce a huge sound wave. In the second stage of mold opening, in order to shorten the cycle time, the moving template moves rapidly to improve the efficiency of machine usage. In the third stage, when the moving template approaches the end position of mold opening, to reduce the inertial impact, the mold opening speed is slowed down. The entire mold-opening process is set with slow, fast and slow speed parameters, and the speed of the mold-locking action is often the same as that of the mold-opening. Taking into account various factors, the purpose of setting speed parameters is to achieve stability, speed and efficiency.

Related News

Injection mold: The "Invisible Creator" in the workshop

2025-07-09

Injection mold: The "Invisible Creator" in the workshopI. First Impression of th...

The causes and solutions of bubbles, mold sticking and gate sticking in injection molded products

2025-07-31

The causes and solutions of bubbles, mold sticking and gate sticking in injectio...

The causes and solutions of dents on injection molded products, incomplete finished products, and flash on products

2025-07-29

The causes and solutions of dents on injection molded products, incomplete finis...

The methods for adjusting parameters for defects in injection molded products are as follows

2025-08-01

The methods for adjusting parameters for defects in injection molded products ar...

The setting of injection molding pressure and flow parameters

2025-07-26

The setting of injection molding pressure and flow parameters1.Setting of inject...

The causes and solutions of poor welding in injection molding, product cracks and product deformation

2025-07-30

The causes and solutions of poor welding in injection molding, product cracks an...