Injection mold gate technology

Injection mold gate technology

Gating system

Auto Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

When designing molds, the selection of gate position and gate form plays a decisive role in the economy of injection molding production.

1.1 The gating system for connecting injection molded parts

1.1.1 Cold runner

For cold runner molds, both the injection molded part and the gate are cooled inside the mold and are simultaneously ejected in each molding cycle.

The key point of cold runner design is to ensure uniform filling of all mold cavities. Therefore, only when the distances from all cavities to the central glue entry point are equal can the filling process be guaranteed to be uniform.

If the cross-sectional area of the feed rod (also known as the runner arm) is too small, a very high injection pressure will be required for the filling of the injection molded part. High injection pressure can cause internal stress, leading to product cracking.

Once the injection pressure is too high, the pressure inside the cavity will also increase. If the clamping force allowance of the injection molding machine is insufficient, the injection molded part will expand.

The cross-sectional area of the diversion channel can be regarded as a function of the product weight, and its reference value is derived from practical experience.

The diameter of the runner should be at least no less than the maximum wall thickness of the injection molded part.

Commodity Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

1.1.2 Three-plate mold runner

The advantage of the three-plate mold is that the injection molded part and the runner can be taken out from two different parting surfaces. This reduces an additional step, namely separating the gate from the injection molded part.

The three-board mold can fill products through one or more openings. This means that there is greater freedom in design compared to two-plate molds. The three-plate mold pouring system is realized by breakable point gates.

When the mold is opened, the drawing rod or drawing hook injected with the mold fixes the runner on the fixed mold. So, the spout was pulled off from the product. There is a mechanism similar to a ejector pin on the fixed mold side to eject the flow channel. One advantage of the three-plate mold is that the spacing between the cavities can be very compact.

It should be noted that the cross-sectional area of the split channel needs to match the product weight, and the split channel should be balanced. Since two parting surfaces need to be opened, one of the surfaces can be delayed in opening, for example.

If possible, wait until the core exits the injection molded part or the thread core is spun and demolded before opening it.

The opening of the three plates, namely the template, the middle plate and the ejector plate, is mostly driven by the injection molding machine. The side lock or pull rod determines the stroke. Pneumatic or hydraulic cylinders are also frequently used to open formwork. Their advantage is that the opening positions of each plate can be controlled by time.

The runner rods often cause production malfunctions. To smoothly remove them from the ancient faulty parts of the mold, they need to be used

Material-taking head manipulator. After programming, the mechanical hand can directly send the material head to the crusher.

1.2 The gating system retained in the mold

1.2.1 Adiabatic flow channel

A mold for retaining the gating system, with a relatively thick cross-sectional area of the flow channel, can maintain the core flow channel (insulating pipe)

The molten state of the plastic in the mold of the retention gating system; Another type is the hot runner system that requires electric heating.

Single-cavity molds directly inject products through a main runner, pre-deposited cavity or heated gate. A multi-cavity mold requires a gating system.

Early molds only used cold runners. Later, a large-capacity gating system formed on the second formwork was added. These channels (also known as "skeletons") remain in the mold. Only thick channels can be insulated, and such molds are called insulated channel molds.

When the mold malfunctions or the material and color are changed, the second template is opened and the runner is removed.

Adiabatic channels are often used for high-speed injection molded parts. The molding cycle of different systems does not exceed 15 seconds.

Typical applications include yogurt cartons, threaded bottle caps, disposable tableware, disposable syringes, pens and planting POTS.

1.2.2 Hot runner

(1) Advantages of hot runners

Hot runner is theoretically an extension of the injection molding unit. It should keep the plastic in the mold cavity in a molten state, guide and heat the molten plastic until it reaches the cavity, while maintaining very little temperature and pressure loss. The hot runner meets the aforementioned requirements.

The greatest advantage of hot runner technology is that there is no waste during the injection molding process and the quality of the injection port is good. There will be no phenomenon of material head sticking together when opening the mold during the production process.

Another advantage is that it is convenient to select the gate position for balanced filling of injection molded parts. Feeding from the center of the bottom of the product is balanced filling, which is suitable for all cylindrical products, such as cups, buckets or similar products.

When the depth of the injection molded part is irregular, all the surfaces of the product can be projected onto a plane, and then another one can be drawn

A circle that accommodates all product areas. If the glue is injected at the center of the circle, it can ensure the balanced filling of the injection molded part.

Eliminating the intermittent runner channels on the parting surface enables the application of brand-new ideas in mold design. The mold can become more compact and the number of cavities can be significantly increased. Molds with 128 or more cavities are not uncommon.

(2) Internal heating type hot runner

Internal heating hot runner molds represent the rise of hot runner technology, but they are rarely used nowadays. One drawback of the internal heating system is that the process of changing colors or materials is very complicated.

The original concept of hot runner technology started from the adiabatic runner concept and developed an internal heat diversion and intake system to prevent plastic solidification in the mold runner. Therefore, the heating system is installed at the center of the diversion channel.

High-temperature raw materials will not overflow from the solidified cold material

It is an important condition for the system's sealing performance. More serious defects will occur during color and material changes. Streaks will appear on injection molded parts because the raw material particles will degrade on the surface of the insulation layer. To avoid these problems, every time the color or material is changed, the entire system needs to be disassembled to remove the raw materials in the distribution pipeline, which is a rather complex process.

The heating system is installed at the center of the flow channel. As a heating element

The simple heating jacket regulates the temperature with the help of sensors. The heating sleeves are almost all self-insulating, so the heat transferred to the mold is very little. This ensures that the thermal expansion is very small, thereby enhancing the sealing capacity of the mold.

Internal heating systems should be given priority for processing semi-crystalline thermoplastics, such as polyethylene (PE), polypropylene (PP), or polyamide(PA).

(3) External heating type hot runner

In the external hot runner, heat is transferred from the outside of the mold to the distributor plate. At this point, the molten plastic in the diversion channel does not come into contact with the heating element.

Wind the heating coil

Most heating elements adopt preformed wound heating coils. First, process grooves on both sides of the diverter plate, then insert the wound heating ring into the grooves, and finally seal it with two-component thermal conductive adhesive. Sometimes, the heating ring is only covered with a thin iron plate. Winding the heating ring can make the heat in the gating system evenly distributed.

Cylindrical heating jacket

As an alternative solution, a simple heating sleeve can be used near the flow channel holes on the split plate. The processing of these holes needs to achieve the best dimensional fit with the heating sleeve to ensure smooth heat transfer.

Simple heating sleeves are usually used in combination with thermal conductive adhesive to ensure good heat conduction and make the replacement of simple heating sleeves more convenient. At present, heating jackets are only used for simple molds.

Related News

Key equipment in the field of logistics and warehousing

2025-06-29

Key equipment in the field of logistics and warehousingTray mold Manufacturer in...

The causes and solutions of silver streaks, discoloration, surface ripples and roughness in injection molded products

2025-07-30

The causes and solutions of silver streaks, discoloration, surface ripples and r...

Multi-component mold

2025-07-25

Multi-component moldIn multi-component injection molding (also known as multi-co...

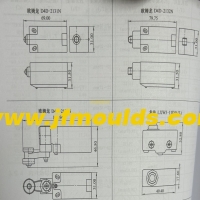

The limit switch of the mold

2025-10-08

The limit switch of the mold In some cases, the actions of different mechan...

Solutions to the problems of air streaks, exposed glass fibers and charring in molds

2025-08-21

Solutions to the problems of air streaks, exposed glass fibers and charring in m...

The screw columns of the mold are prone to damage and weld marks/shrinkage

2025-08-07

The screw columns of the mold are prone to damage and weld marks/shrinkageThe sc...