Solutions to the problem of easy breakage at the junction of the mold's appearance color difference and material flow

Solutions to the problem of easy breakage at the junction of the mold's appearance color difference and material flow

The color difference in the appearance of the mold

Phenomenon: There is a color difference in the surface appearance of the front shell of the casing product during the production process.

Analysis: High shear force and thermal decomposition of the material flow; The raw material melt adhesive is uneven. The product color is sensitive and can easily cause visual differences.

Characteristics of injection molding machines

Grade: HT-DEMAG Clamping Force: 100t Plasticizing capacity :150g

(2) Mold characteristics

Mold ejection quantity :1×2, glue injection method: point gate, ejection method: pin ejection, mold temperature :105℃ (constant temperature machine)

(3) Product characteristics

Material :ABS+PC, Color: Black, Product weight (single piece) :5.5g, nozzle weight :3.3g

(4) Analysis of causes of defects

The main runner of the mold is quite large. The glue injection method is point injection. The high shear force and thermal decomposition of the material flow, as well as the uneven melting of the raw material, are the causes

The phenomenon of color difference on the surface appearance of the product.

(5) Countermeasures

The raw materials are thoroughly dried to reduce moisture content.

Enhance the plasticizing capacity of raw materials and maintain uniform plasticizing.

Exhaust gas is added to the mold.

Improve the uniformity of the cooling waterways in the mold.

Adopt multi-stage injection molding and increase the mold temperature.

Reduce the temperature of the barrel.

Reduce the injection speed.

Shorten and stabilize the production cycle and reduce the residual amount.

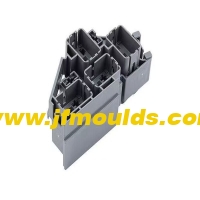

Flowerpot mold Manufacturer in China (jfmoulds.com)

The material flow junction of the mold is prone to breakage

Analysis: The fluidity of the raw materials is poor; At the junction of the material flow, the gas cannot be discharged,

resulting in insufficient combination.

Characteristics of injection molding machines

Grade :DEMAG, clamping force: 100t, plasticizing capacity: approximately 150g

(2) Mold characteristics

Mold ejection number :1 ×2, glue injection method: Water injection with ox horn, ejection method: Ejection with ejector pin, mold temperature :110℃ (oil temperature machine)

(3) Product characteristics

Material: ABS+PC GN-5001RFH, Color: Gray, Product weight (single piece) : 0.73g, spout weight: 7.74g

(4) Analysis of causes of defects

1. The raw materials have poor fluidity.

2. Poor exhaust at the junction.

(5) Countermeasures

1. Replace the raw materials with good fluidity and toughness: Change from LG ABS+PC HP 5004S+ color powder to LG ABS+PCGN-5001RFH+ color powder

2. Cut in the material flow junction to enhance the exhaust effect.

Related News

The setting of injection molding pressure and flow parameters

2025-07-26

The setting of injection molding pressure and flow parameters1.Setting of inject...

Solutions for delamination, peeling, hardening and fragility of injection-molded products

2025-08-01

Solutions for delamination, peeling, hardening and fragility of injection-molded...

The methods for adjusting parameters for defects in injection molded products are as follows

2025-08-01

The methods for adjusting parameters for defects in injection molded products ar...

Solutions to problems such as poor transparency, unstable dimensions, spots, and black lines in injection molded products

2025-07-31

Solutions to problems such as poor transparency, unstable dimensions, spots, and...

From technological breakthroughs to intelligent transformation

2025-07-07

From technological breakthroughs to intelligent transformation Injection mol...

The causes and solutions of bubbles, mold sticking and gate sticking in injection molded products

2025-07-31

The causes and solutions of bubbles, mold sticking and gate sticking in injectio...